Reduction of Carbon footprint in Control Rooms by proper design

One of the main challenges of a control room design expert is focusing on carbon footprint reduction that is paramount in ensuring the sustainability and environmental responsibility of the facility. It is essential to integrate a holistic approach that addresses various aspects of the control center's operations to effectively minimize its carbon footprint.

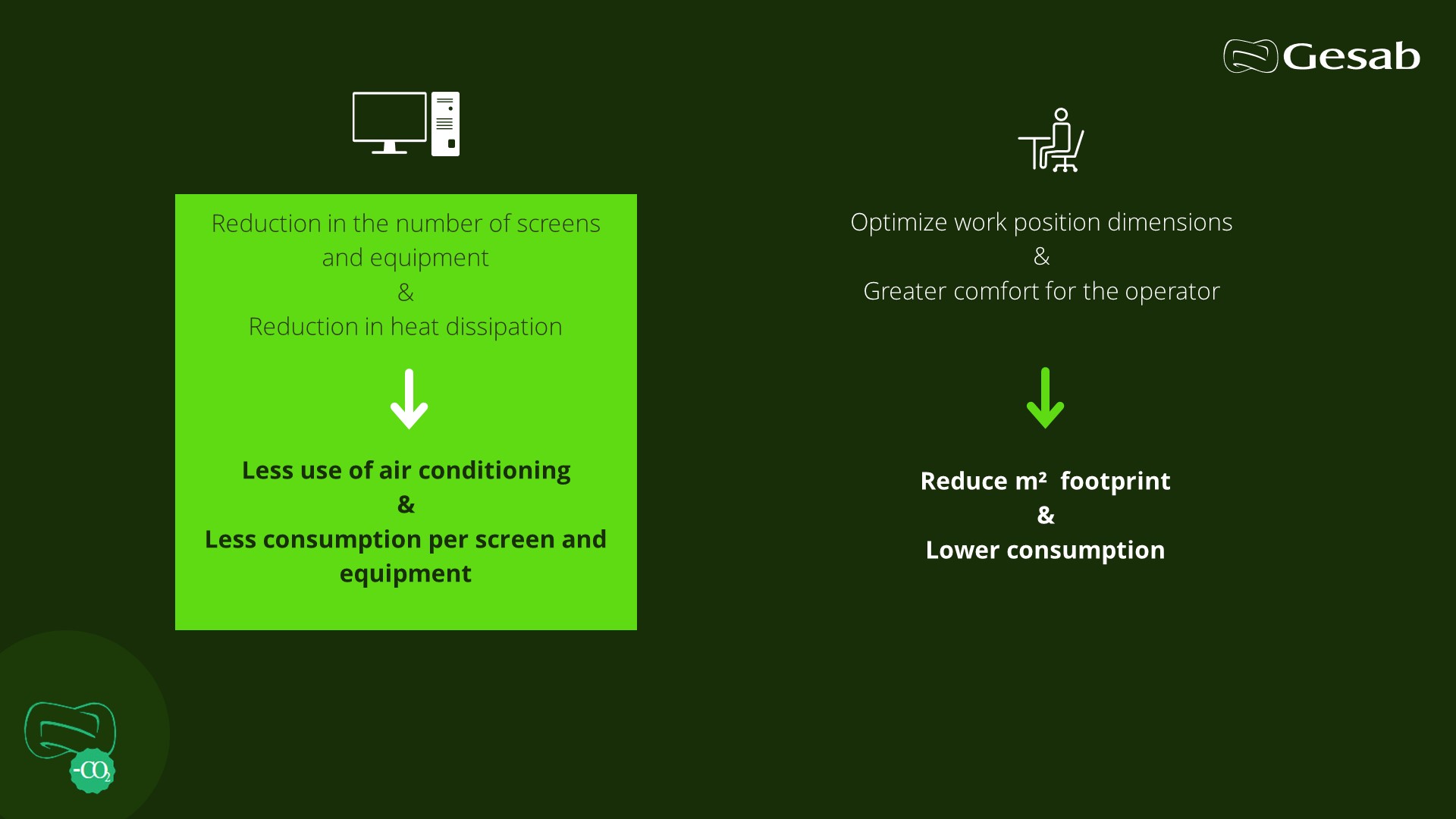

One of the key strategies to achieve this goal is through the optimization of energy efficiency within the control room. This can be accomplished by deploying state-of-the-art, energy-efficient equipment and leveraging advanced technologies that consume less power while maintaining optimal performance. Implementing energy-efficient lighting systems, such as LED adjustable lighting perhaps with motion sensors, and employing automated lighting controls can significantly reduce energy consumption. Furthermore, utilizing smart HVAC systems that regulate temperature based on occupancy and outdoor conditions can effectively manage energy usage, thereby minimizing the control room's overall carbon emissions.

In addition to energy efficiency, the design and layout of the control room play a crucial role in reducing the carbon footprint. Opting for a minimalistic approach in hardware deployment within the control room not only conserves energy but also reduces the overall demand for raw materials used in manufacturing electronic devices. This streamlined hardware setup, such as the one you con find in IP KVM Enhanced solutions not only promotes a cleaner aesthetic and reduced use of space but also contributes to lower energy consumption and a reduced carbon footprint.

Moreover, the establishment of a remote equipment room, which is isolated and temperature-controlled, serves as a highly professional solution to further reduce the carbon footprint. By centralizing the control room's equipment in a separate, optimized environment, the need for excessive cooling and heating within the main control room is significantly minimized. This results in reduced energy consumption for maintaining optimal temperature conditions, thereby contributing to a notable reduction in the facility's carbon emissions.

Integrating renewable energy sources, such as solar panels, also plays a pivotal role in carbon footprint reduction. By harnessing clean and sustainable energy, the control center can significantly decrease its reliance on non-renewable energy sources, thereby effectively lowering its overall carbon emissions. Furthermore, implementing energy storage systems, such as batteries, enables the storage of excess energy generated during peak times for later use, ensuring a continuous and sustainable power supply while further reducing the facility's carbon footprint.

Considering the carbon footprint implications in the selection of materials used for construction and furnishing is crucial. Opting for sustainable building materials, such as recycled steel and responsibly sourced wood, not only minimizes the carbon emissions associated with raw material extraction and production but also promotes the concept of circular economy within the facility. Additionally, utilizing eco-friendly paints and finishes with low volatile organic compound (VOC) emissions such as Greenguard certified furniture ensures a healthier indoor environment and contributes to the overall reduction of the control room's carbon footprint.

In summary, as a control room design expert, prioritizing energy efficiency, implementing innovative design solutions, integrating renewable energy sources, and consciously selecting sustainable materials are crucial steps in significantly reducing the carbon footprint of the control center. By incorporating these strategies into the design and operational practices, the control center can effectively demonstrate its commitment to sustainability and environmental stewardship.

Recommended Content

Creating the Next Generation AV Workforce: From Audio Engineers to Solution Designers

Please sign in or register for FREE

If you are a registered user on AVIXA Xchange, please sign in