How Carbonite HyperMax solves the problem of underutilized production equipment

With yesterday’s production technology, a three hundred thousand dollar switcher might have idled for over half of the day. Today, that same silicon can drive three concurrent shows, across multiple studios.

What changed? Forward-thinking engineers stopped locking capacity inside single-purpose hardware and started treating MEs, keyers, and scene engines as portable software licenses that can be assigned to flexible hardware solutions.

Below, we’ll unpack the hidden costs of purpose-built gear, show how dynamic licensing flips budget drains into productivity gains, prove the impact through Ross Video’s Carbonite HyperMax platform, and leave you with a clear ROI checklist and next-step playbook.

The hidden costs of fixed broadcast hardware

A traditional switcher or effects engine looks busy when its fans spin and LEDs glow, but diagnostics tell a different story. High-end engines inside newsrooms can often sit idle for 50-75% of the day.

That under-use can impact virtually every department within the organization, including:

- Finance – Every component continues to depreciate whether its generating revenue or gathering dust.

- Production – Since single-function hardware can’t “flex” when more inputs or effects resources are needed, the creative team is often forced to make unnecessary compromises.

- Engineering – In order to meet the demands of News or Production, Engineering must design, purchase, install, and maintain duplicate hardware to cover peak periods.

Additionally, the entire organization feels the impact of “hidden” operating expenses like power consumption, cooling costs, and increased space requirements.

Fixed-function boxes worked well when each show was linear and all were produced in the same format and sent to the same transmission point. But in the 24/7, multi-format, multi-destination world that broadcasters live in today, capacity has to move at the speed of the schedule, not the limitations of purpose-built hardware. The answer is to treat processing power as a shared pool, not a stack of siloed frames.

This is where software-defined hardware and dynamic licensing dramatically changes the game.

Dynamic licensing: a new model for production agility

Picture a switcher that behaves less like a monolithic appliance and more like a shared pool of resources. That’s the essence of dynamic licensing.

Dynamic licensing, like that offered through the Carbonite HyperMax system, treats advanced switcher effects modes as portable software based modules that can be assigned wherever they’re needed—on-prem, in an OB van, or halfway across the world.

At the heart of the system sits Ross Platform Manager (RPM), a control layer that assigns and reassigns features across multiple hardware platforms and can transfer resources in real-time without rewiring or major system downtime.

RPM allows engineers to drag-and-drop processing capacity across all connected frames as demand or needs change. For example, if Control Room A is off-air after the morning show, its ME licenses can be reassigned to the REMI hub for an afternoon soccer match, then reclaimed for prime-time news.

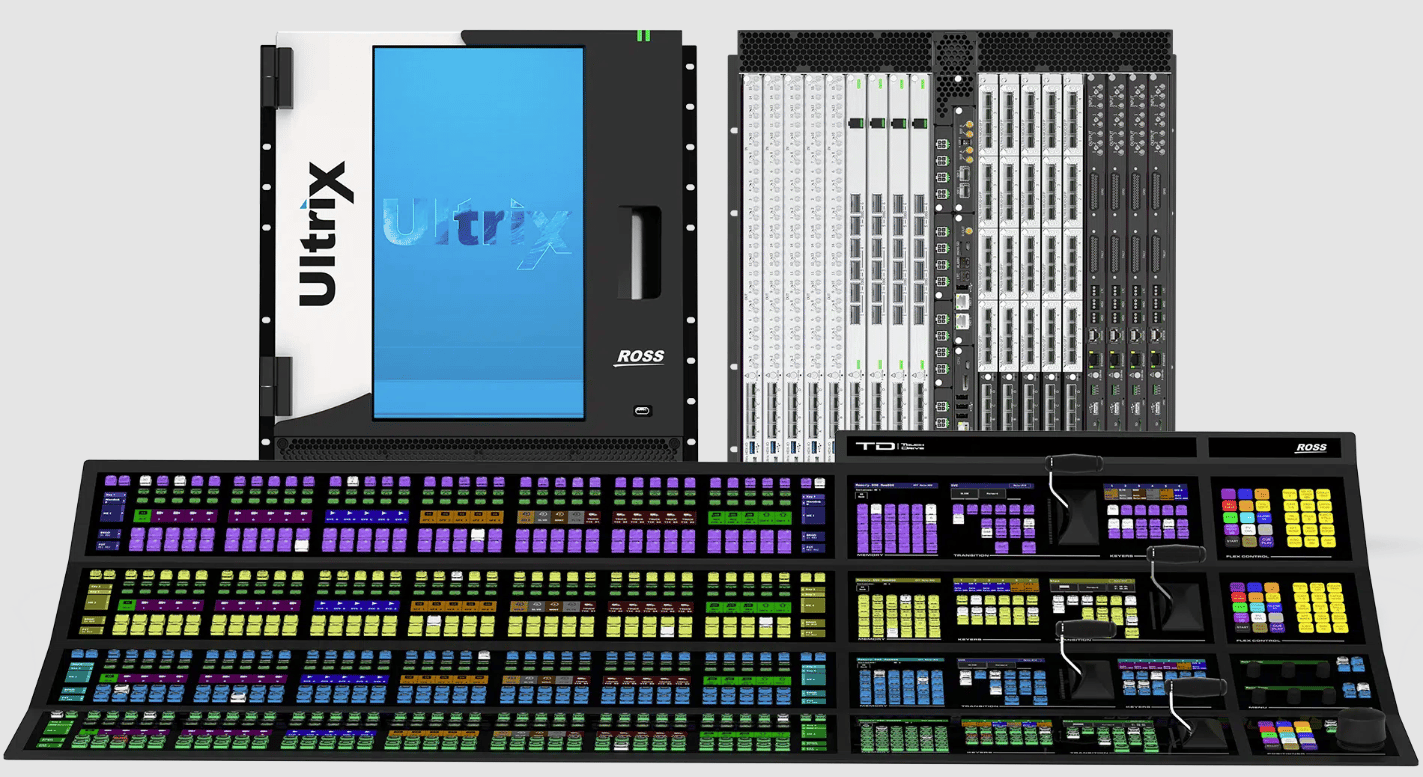

Operationally, HyperMax licenses are assigned to Software-Defined Production Engine (SDPE) hardware blades, which are mounted in an Ultrix advanced routing and processing platform. Each blade can be licensed as a MaxME (a full-featured ME), a group of MiniMEs (each with its own transition effects), or a MaxScene for scene-based compositing. Multiple blades can also be pooled together to build larger switcher configurations.

Nigel Spratling, VP of Production Switchers at Ross, sums it up by saying that:

HyperMax is designed with flexibility and scalability in mind. Dynamic licensing lets news producers modify and expand functionality to meet demand while maximizing ROI.

READ THE FULL BLOG

Please sign in or register for FREE

If you are a registered user on AVIXA Xchange, please sign in